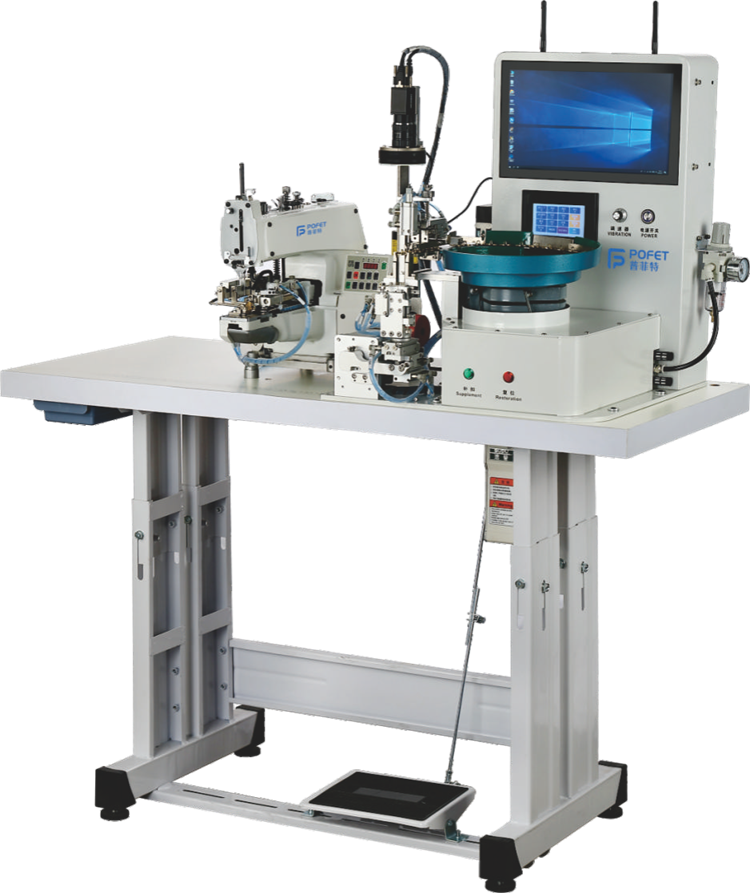

Functional Features / Key Characteristics:

1、Equipped with a touchscreen operating system, offering more stable software and an intuitive interface

2、Two feeding modes are available: Standard Mode and Large-Button Rapid Mode, allowing free switching as needed.Standard Feeding: Buttons are fed directly from the feeding chute to the button clamp.Large-Button Rapid Mode: When the "Large-Button Rapid" parameter is enabled, buttons are pre-fed to a standby position between the feeder and the button sewer (standby position is adjustable), achieving faster feeding compared to the standard mode

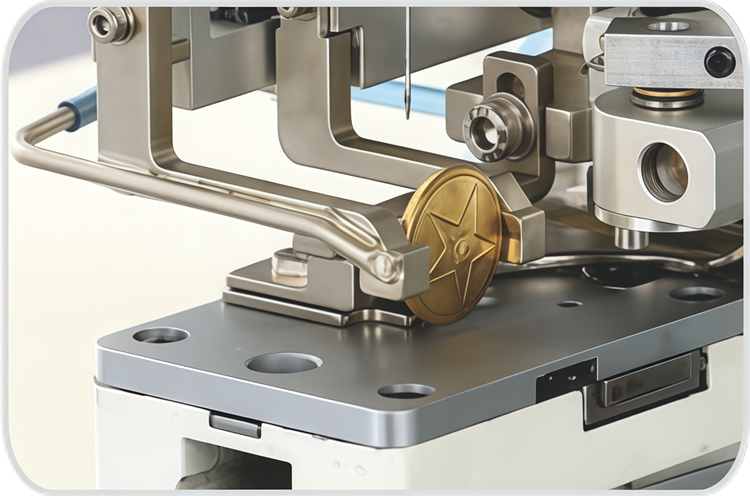

3、Button Shank Length Adjustment Mechanism:The button shank length on the machine arm can be quickly adapted to different button shank sizes by adjusting a screw, providing convenient and rapid operation

4、Button Clamping and Pressing System:Utilizes a cylinder-driven pressing mechanism to ensure precise button positioning without deviation, achieving more secure and stable clamping

5、Button Feeding System:Features a uniquely designed, streamlined feeding chute with bottom and top air-blowing functions to prevent jamming and ensure smooth button delivery.

Timed Reverse Air Blow Device:Prevents buttons from clogging at the chute entrance, guaranteeing continuous and stable feeding

6、Servo Motor Drive:A high‑power servo motor is used for button feeding, delivering high‑speed operation with minimal vibration and low noise, significantly improving feeding efficiency

Customizable Combinations / Flexible Pairing:

This device is compatible with button sewing machines of various brands and models, such as Juki and Brother, and can also be integrated with existing button sewers already in use at garment factories, significantly saving the cost of purchasing new button sewing machines

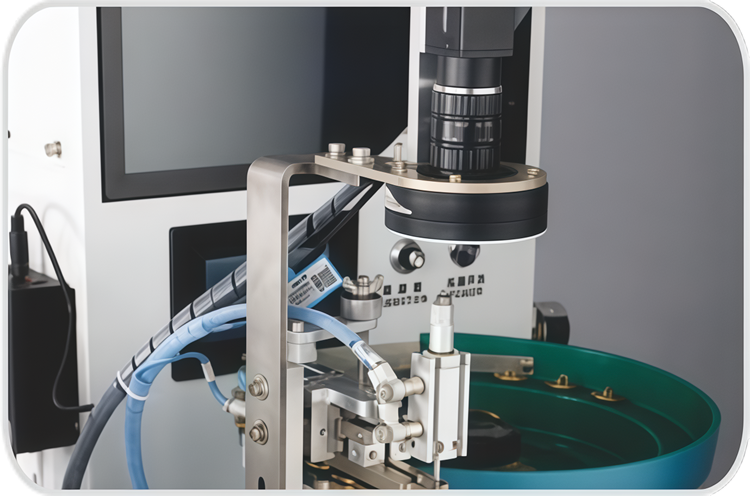

Logo Visual Recognition Button Placement Device:

The Logo Visual Recognition Button Placement Device is an intelligent system that integrates machine vision technology with automated control. Its core function is to accurately identify the logo orientation of buttons in real time through a high‑precision vision system, and simultaneously drive the mechanical mechanism to achieve automated precision positioning and attitude correction for button placement

| Model | YS-998-1903 | YS-998-438 | YS-998-373 |

| Configuration | 1903D | 4380 | 373D |

| Needle(DP*17) | MT*190-14 | TV*5-14 | TQ*7-14 |

| Number of Needles | 1 | 1 | 1 |

| Rated Button Sewing Speed(PCS/min) | 40-50 | 40-50 | 40-50 |

| Continuous Button Sewing Speed(PCS/min) | 60-65 | 60-65 | 60-65 |

| Maximum Speed (RPM) S.P.M | 2600prm | 2600pm | 2600pm |

| Presser Foot Lift Height(mm) | 12 | 12 | 12 |

| Button Diameter(mm) | 8-28 | 8-28 | 8-28 |

| Button Thickness(mm) | 10 | 10 | 10 |

| Air Pressure | 0.35-0.40 | 0.35-0.40 | 0.35-0.40 |

| Voltage | VAC110/220V±10%: 50/60Hz | VAC110/220V±10%: 50/60Hz | VAC110/220V±10%: 50/60Hz |

| Rated Power | 600+750 | 600+750 | 600+750 |

| Button Feeding Stability | 99.70% | 99.70% | 99.70% |

| Packaging Dimensions(mm) | 580x550x460 | 1250x750x1220 | 1250x750x1220 |

| Weight | 134kg | 134kg | 134kg |

Address: 4th Floor, Building 9, Hongdi Kechuang Park, Xiachen Street, Jiaojiang District, Taizhou City, China

Tel: +86-576-88661601

Mobile: +86-13867633022

E-mail: yisuofrj@hotmail.com

Copyright © 2025 Taizhou Yisuo Sewing Machine Co., Ltd.