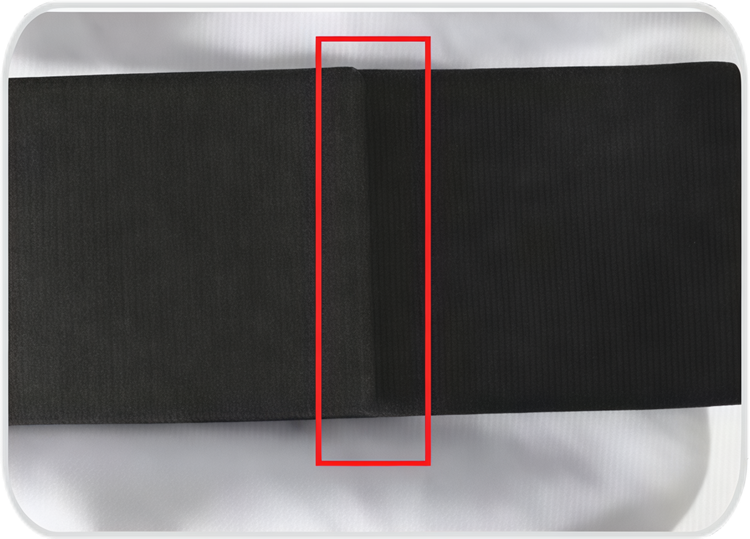

Weld‑Bonding First

Followed by Pattern Sewing

Final Product Effect

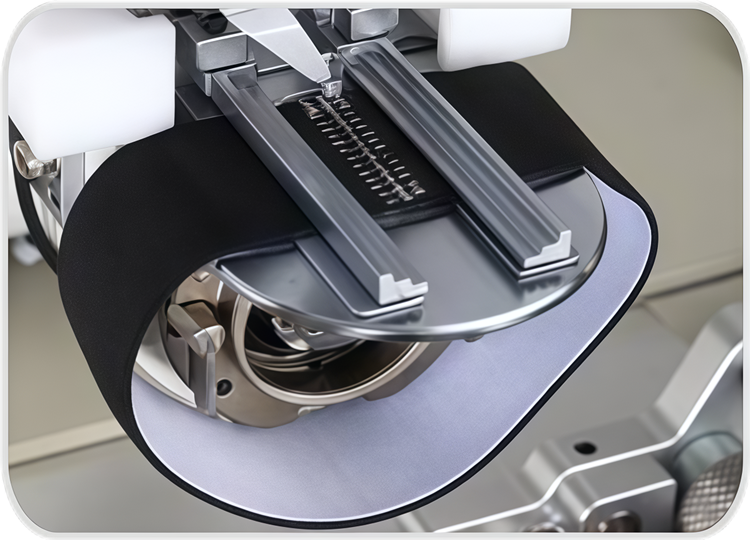

Following Camera

High Efficiency & 1 Machine = 5 Manual Workers

Uniform Quality & Stable High Efficiency

1、Automatic loading, feeding, cutting, sewing, and unloading — for jacquard elastic bands of standard sizes, production capacity reaches 750‑1000 pieces per hour

2、Compatible with various sewing machine brands; processes jacquard elastic bands with visible‑elastic craftsmanship — resulting in strong, aesthetic, neatly aligned, and accurately coded products

3、Splicing Width: 20mm~50mm

4、Sewn elastic band length (folded) > 150mm

5、Automatic Stop and Alarm for Missing Needle Thread or Elastic Band

6、Suitable for various elastic splicing processes, widely applicable to elastic band joining in underwear, children's wear, and sportswear — delivering superior results with smooth and aesthetically pleasing stitches

7、Equipped with the most advanced domestic vision system, capable of recognizing both monochrome and multi‑color elastic band logos

Attention:CSB:Ultrasonic Cutter X:Camera

| Model | YS-1906-SST |

| Cutting Tool | Ultrasonic Cutter |

| Width | 1-5cm |

| Minimum Diameter | 11-15cm |

| Needle(DP*17) | #11-16 |

| Sewing Speed | 2200pm |

| Sewing Stitch | Zigzag Stitch |

| Air Pressure | 0.5Mpa、1.8L/min |

| Voltage | Single‑Phase 220V |

| Packaging Dimensions(mm) | 1600x120x1400 |

| Weight | 400kg |

Address: 4th Floor, Building 9, Hongdi Kechuang Park, Xiachen Street, Jiaojiang District, Taizhou City, China

Tel: +86-576-88661601

Mobile: +86-13867633022

E-mail: yisuofrj@hotmail.com

Copyright © 2025 Taizhou Yisuo Sewing Machine Co., Ltd.